Bridges, in both their simple and majestic forms, stand as symbols of connection and progress. They link communities, facilitate commerce, and enable transportation. Behind these structures lies a critical element often overlooked—the art of metal fabrication. In this article, we delve into the world of bridge construction and maintenance, highlighting the indispensable role of metal fabrication in bringing these engineering marvels into productive use.

The Backbone of Bridges

Bridges, whether spanning rivers, valleys, or highways, require a sturdy skeletal framework that can withstand immense loads and environmental forces. This is where large metal fabrication comes into play. The importance of metal fabrication in bridge construction cannot be overstated. Here’s why:

-

1. Strength and Durability:

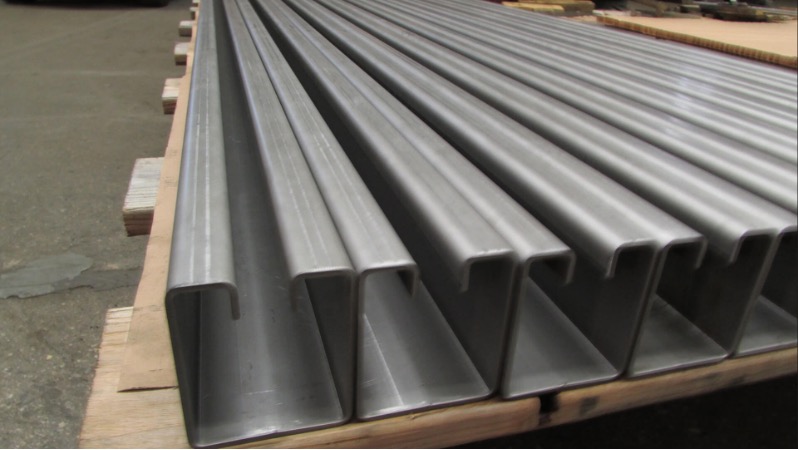

Metal, particularly steel, is renowned for its strength and durability. It can withstand heavy traffic, harsh weather conditions, and the test of time. Metal fabrication ensures that the bridge’s components, from beams to brackets and supports, are manufactured to endure.

-

2. Precision Engineering:

Bridges demand precision engineering to ensure safety and longevity. Metal fabrication allows for the precise cutting, welding, and shaping of components to meet exact specifications, ensuring the structural integrity of the bridge.

-

3. Customization:

Every bridge project is unique, with specific requirements as well as design and engineering constraints. Customized metal fabrication enables engineers and designers to create bridges that fit the landscape, fulfill transportation needs, and adhere to safety regulations.

Stages of Metal Fabrication in Bridge Construction

-

1. Design and Planning

The process begins with meticulous plans. Engineers and architects work in close collaboration with metal fabricators to conceptualize the bridge’s structure. Specific metals are chosen for their desired strength and the fabrication techniques are carefully determined.

-

2. Material Selection

Steel, due to its exceptional tensile strength (strength-to-weight ratio), is a popular choice for bridge construction. The type and grade of steel are determined based on such factors as the bridge’s location, load-bearing capacity, and anticipated environmental conditions.

-

3. Cutting and Shaping

Once the materials are chosen, they are cut and shaped according to the design specifications. Advanced cutting technologies like laser cutting and waterjet cutting ensure precise and clean edges, crucial for a secure fit during assembly.

-

4. Welding and Assembly

Welding is a fundamental process in most metal fabrication projects. Skilled welders meticulously join the components together, creating the bridge’s framework. The quality of welds is of utmost importance to ensure the bridge’s structural integrity.

-

5. Surface Treatment and Coating

Bridges are exposed to the elements, making surface treatment and coating essential for protection against corrosion and rust. Metal fabricators apply coatings that withstand weather, salt, water, and other corrosive elements to help extend the bridge’s lifespan.

-

6. Transport and Installation

Once the bridge components are fabricated, they are transported to the construction site and assembled. This process demands that components are sized and shaped with precision and that installation is well coordinated to ensure good fit and structural integrity.

Maintenance and Repairs

Metal fabrication doesn’t end with bridge construction. Regular maintenance is crucial to preserving the bridge’s functionality and safety. Metal fabricators play a vital role in inspecting, repairing, and reinforcing bridge components, and supplying replacements as needed over time.

At Gilchrist Metal Fabricating, we are proud to contribute to the construction and maintenance of numerous bridges in New England and beyond. Our dedication to quality, precision, and customization ensures that every bridge component project we undertake is a testament to the endurance of high-quality metal fabrication.

“Don’t Burn Any Bridges”

Bridges are remarkable feats of engineering, and at their core lies the artistry of metal fabrication. The importance of large metal fabrications in bridge construction and maintenance cannot be overstated. It provides the strength, durability, and precision necessary to create these vital connections that link communities and fuel progress.

If you have any inquiries or would like to learn more about our metal fabrication services for bridge construction and maintenance, or any other application, please feel free to contact us. We’re always happy to help build the bridges that connect our world.