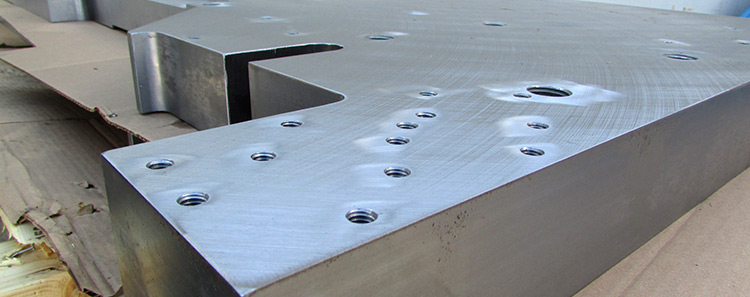

Since our doors first opened, one of GMFCO’s core specialties has been large CNC machining. In our modern New England facility, advanced equipment and decades of know-how come together to provide some of the region’s most extensive large machining capabilities — all under one roof.

Whether you need precision boring, milling, or complex custom parts, our team is uniquely equipped to deliver large CNC machining services that meet tight tolerances and demanding timelines.

Where others see problems, we see opportunities.

At GMFCO, our drive to consistently offer more is what sets us apart. By combining cutting-edge technology with experienced machinists, we excel at projects many shops can’t accommodate. Finding solutions where others see limitations is our specialty — and it’s why customers from industries across the U.S. trust us for large custom CNC machining service.

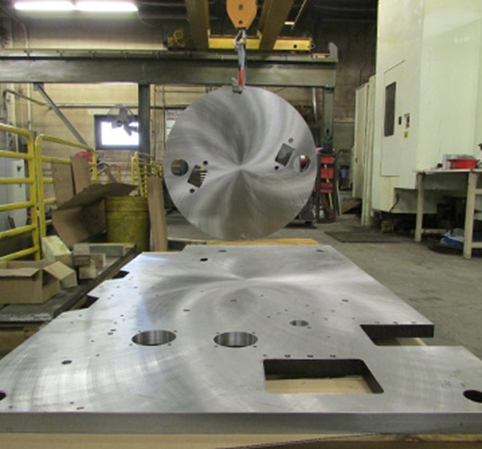

Handles components up to 275” long x 135” wide x 96” high and 44,000 lbs.

Toshiba CNC Horizontal Boring and Milling

5th Axis Rotary Table: 98“ X, 70“ Y x 57“ Z, 3000 RPM

Mori Seiki NV 5000

12,000 RPM spindle speed, 2.6 second chip-to-chip tool change time

5 ft x 27 ft work envelope

Rotary positioning of pipe and tube up to 75 ft long

6000 RPM spindle speed

From aerospace and defense to construction and architecture, companies in every industry rely on us for large, complex projects. We work closely with clients from the planning stage through final inspection, ensuring precision, communication, and on-time delivery.

Having all of our large CNC machining services under one roof allows us to maintain consistent quality, reduce lead times, and keep projects on budget.

Our customers depend on us for:

Precision machining of oversized or complex components

Custom CNC machining tailored to unique specifications

Scalable production for prototypes, short runs, or large volume projects

Experienced quality control to meet demanding standards

With years of experience serving industries where failure is not an option, we’ve built a reputation as the trusted partner for large custom CNC machining service that delivers results every time.

If you’re looking for a machining partner with the equipment, experience, and dedication to handle your most challenging projects, GMFCO is ready.

Contact us today to discuss your requirements and see how our large CNC machining services can help you achieve precision, efficiency, and success.

Maximum Size: 275" Long x 157" Wide x 96" High X 44,000 LBS

Multi Axis Machining: 4 and 5 Axis Machining

*NEW* AweA Double Column 5-Face Machining Center: for components as large as 275” Long x 157” Wide x 96” high x 44,000lbs

CNC Horizontal Machining: Toshiba CNC Horizontal Boring and Milling: 5th Axis Rotary Table 98“ X, 70“ Y x 57“ Z, 3000 RPM.

CNC Vertical Machining: Mori Seiki NV 5000; 12,000 RPM spindle speed, 2.6 second chip to chip tool change time

Quickmill Gantry Machining Center with Pipe Rotation Fixture: 5 ft x 27 ft, Rotary Position of pipe and tube up to 75 ft long, 6000 RPM