GMFCo Produces Large Copper Fabrications for MIT Plasma-Fusion Experiment

MIT – the Massachusetts Institute of Technology – has partnered with private industry to create the world’s highest-performance magnets to be used in the development of fusion energy. When this experimental work is successfully completed, these magnets will be deployed in building the first controlled fusion energy production experiment known as “SPARC.” The experiment offers great promise to revolutionize clean energy production. Power may become much cheaper and cleaner, and the fuel source is virtually unlimited.

Power Generation Breakthrough?

“SPARC,” a compact, high-field, net fusion energy initiative, will validate a high temperature, superconducting technology and advance the creation of the world’s first fusion energy reactor. This technology could potentially power us through the next millennia.

“SPARC,” a compact, high-field, net fusion energy initiative, will validate a high temperature, superconducting technology and advance the creation of the world’s first fusion energy reactor. This technology could potentially power us through the next millennia.

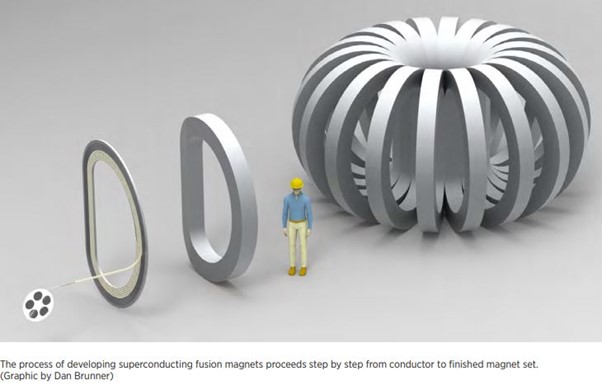

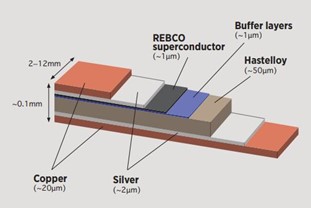

GMFCo is playing a critical role by manufacturing large copper D-shaped ring fabrications that serve as crucial layers in the “tapes” or “ribbons” used for building super high-performance magnets. Such magnets are required in the physics to create an environment where a fusion reaction can take place and produce net energy.

Science & Technology Solving Global Problems

The science behind this ambitious project is as fascinating as it is complex. So much theoretical and experimental progress has been made in fusion energy science that now the MIT Plasma Science & Fusion Center, in collaboration with Commonwealth Fusion Systems, is advancing the design for the actual building of SPARC.

MIT has dedicated a microsite to this experiment which delves into the history, science and ongoing work of the project. Learn more by visiting https://www.psfc.mit.edu/sparc.

Scaling Precision Fabrications to Size

As the world turns and technology never rests, GMFCo remains committed to being on the leading edge of large metal fabrication and precision machining. Our role in the SPARC initiative resulted in part from the challenge of finding a fabricator to produce the needed copper layers at the size and tolerance required for SPARC’s superconducting ribbons.

The opportunity to work with MIT on the SPARC project is another case of answering the call of our motto, “where others see problems, we see opportunities.” It’s in our DNA to support the science and engineering behind building more complex and amazing machines that help improve our lives.

If you have a large metal fabrication or machining challenge, talk with us. We’re always listening for opportunities to offer breakthrough solutions to manufacturing challenges.