GMFCO Is the One-Stop Shop for Large Metal Fabrications

In large part metal fabrication and machining, complexity tends to be the rule. Most projects require multiple coordinated steps. Cutting, bending, welding, machining, finishing, stress relief, and inspection each require special equipment, expertise, and scheduling demands. For many organizations, that multifunction complexity turns into a maze of vendors, purchase orders, timelines, and added risk.

Removing the Friction

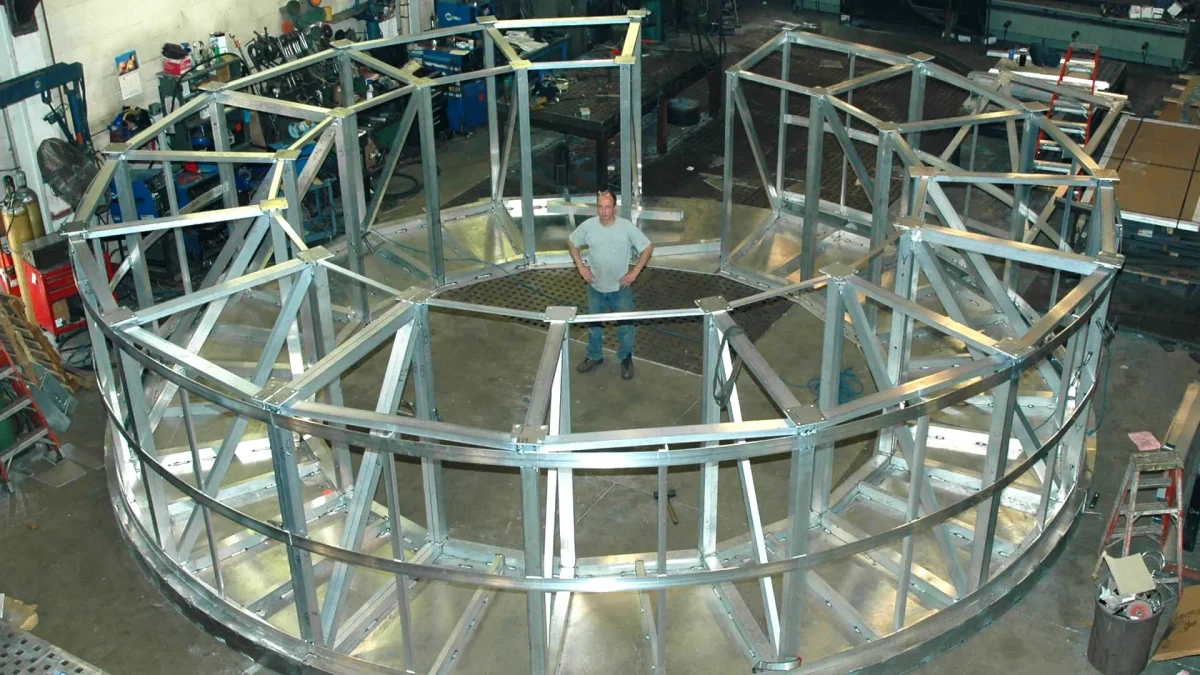

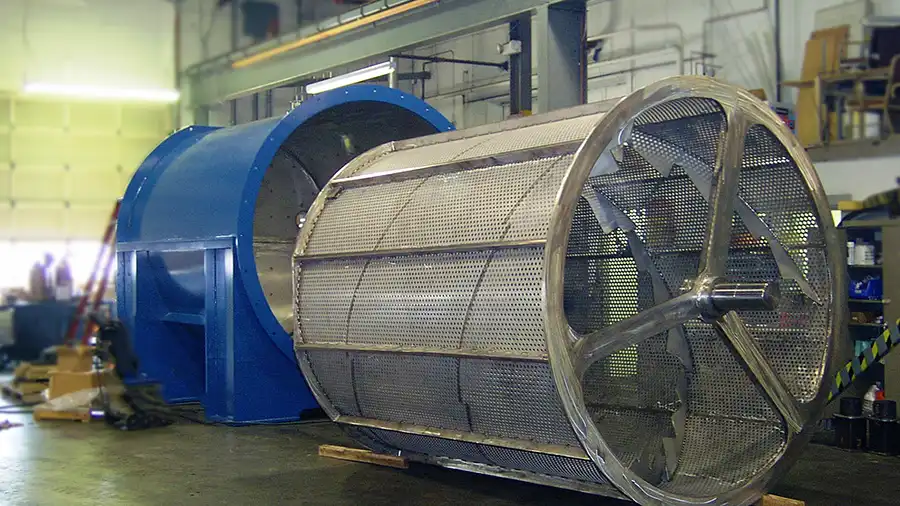

One of our primary goals is to give customers a single, trusted partner for large, precision metal work. Our team can manage the entire scope of a project, from raw material to finished assembly. Most of that work happens in-house within our 70,000-square-foot facility in Hudson, New Hampshire. When a project requires a specialized process beyond our walls, we bring in carefully selected strategic partners to complete the job under our direction.

Founder Jack Gilchrist calls these relationships “tight and right.” They are long-standing, proven collaborations with specialists who share our standards for quality, responsiveness, and accountability. Whether the work stays in-house or extends to a trusted partner, GMFCO remains fully responsible for the outcome.

This is the reality of most “single source” suppliers and how one-stop-shop sourcing really works in most manufacturing companies.

Designed for Integration and Scale

GMFCO is structured to handle large and complex work without fragmentation. Under one roof, we provide:

- Large CNC machining for parts up to 275″ long and 44,000 lbs

- Large custom CNC milling services for precision features on massive components

- Large metal machining for both standalone parts and welded assemblies

- A full large metal bending shop with long high-tonnage press brakes

- Structural and precision welding

- Cutting, rolling, forming, assembly, and inspection

For many projects, everything happens inside our facility from the first cut to final assembly. This gives customers clear advantages:

- Fewer handoffs

- Tighter schedules

- Better communication

- Consistent quality from start to finish

Instead of managing three, four, or five vendors, clients work with one team responsible for the entire outcome.

Supervising Specialized Work

Even the most capable fabrication shops encounter operations better handled by a specialty provider. Such might include:

- Wire EDM for ultra-precise internal features

- Specialized grinding

- Heat treating

- Surface coatings or plating

- Non-destructive testing

- Specialized finishing processes

Rather than pushing those responsibilities onto the customer, GMFCO works with trustworthy partners to absorb them into the project flow. We select the right partner, coordinate schedules, manage logistics, and integrate the work seamlessly into the overall plan. Most importantly, we remain the single point of accountability.

Quality assurance stays with GMFCO. Delivery commitments stay with GMFCO. Communications flow from one point of contact. From the customer’s perspective, the complex is made simple. There is always one project manager, one timeline, and one organization responsible for your finished products.

This approach turns what could be a multi-vendor headache into a reliable and predictable process.

Project Management as a Core Capability

Large fabrication projects succeed or fail on communications and coordination. Material lead times, machining schedules, welding sequences, and finishing steps must align. Delays compound quickly. Miscommunication leads to costly rework.

At GMFCO, project management is a fundamental skillset and capability. Every job is guided by a team that understands how fabrication, machining, and finishing come together. When external specialists are involved, we integrate them into that workflow with the same rigor we apply in-house. Drawings, tolerances, schedules, and inspection requirements are controlled by GMFCO so nothing is left to subjective interpretation.

The result is a process that feels simple to the customer, even when to us, the actual work can be a rigorous process.

Single Source Advantages

For organizations working with large and complex metal components, one-stop partnering makes the most sense, even when your procurement team knows its stuff. Why?

- Reduced risk – One accountable partner eliminates finger-pointing between vendors.

- Shorter timelines – Integrated planning prevents gaps between operations.

- Lower administrative burden – Fewer POs, fewer vendors, fewer meetings.

- Consistent quality – One set of standards governs every phase.

- Clear communication – One team that knows the full scope of the project.

Whether a customer needs a one-off prototype or a production run of large machined assemblies, the experience is the same: clarity, control, quality, and confidence.

Committed to Best Results

Plenty of shops can boast big machines or wide-ranging services. What differentiates GMFCO is the way those capabilities are brought together. We make everything under our roof when possible, and through our “tight and right” partnerships when necessary. We don’t just fabricate parts. We assume ownership of project results.

For customers seeking a large CNC machining shop or a partner for complex, large-scale metal fabrication, that distinction matters. It means fewer surprises, better results, and a relationship built on trust.

At GMFCO, “one-stop-shop” doesn’t always mean we do everything ourselves. It means you only need one partner who stands behind evert product that goes out the door.