Gilchrist Metal Fabricating Company of Hudson, New Hampshire has recently announced plans to implement facility expansion and equipment upgrades by the end of April, 2016.

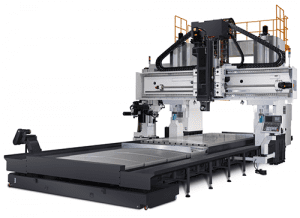

The expansion of Gilchrist Metal Fabricating Company’s 70,000 sq. foot metal fabrication and machining facility coincides with the acquisition of an AweA Double Column 5-face machining center, which will provide advanced large machining for small and large volume fabrication projects. In order to suit the machine, the company’s facility at 12 Park Ave in Hudson, NH, GMFCO is raising the roof!

With its heavy duty working-table, large multi-axis travel, and highly flexible machining heads, the new 5-face machining center will allow GMFCO to accommodate larger machining projects with greater efficiency and speed.

GMFCO’s President Jack Gilchrist regards this major facility addition as both pragmatic and strategic. The implementation of a new 5 axis machining center will make the company one of few metal fabricators in New England capable of high volume large capacity machining for parts and components as large as 275’’ long X 157’’ wide x 96’’ high X 44,000 lbs.

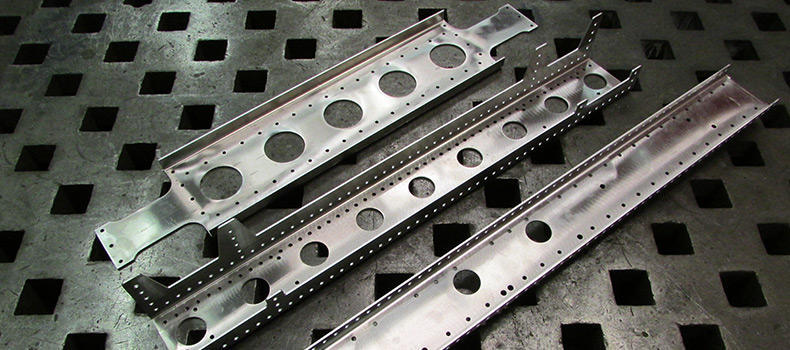

This addition will enable GMFCO to provide a wider variety of customers with the large machining required for parts and components vital to industries and applications ranging from general construction and architectural steel to power generation, marine components, food processing equipment, and beyond. With its large capacity tool changer for milling and drilling tooling as well as two 90 degree angle heads and state of the art material handling system, the new bridge mill will also allow GMFCO to provide large machined fabrications faster and more efficiently, accommodating the ever-growing demand for greater cost efficiency and tighter production schedules.

With facility expansions slated to be complete by April 15th, the new 5 axis machine is expected to be fully operational by April 30th.