How GMFCO Tackles Large and Oversized Parts: From 75 Foot Masts to 44,000 Pound Fabrications

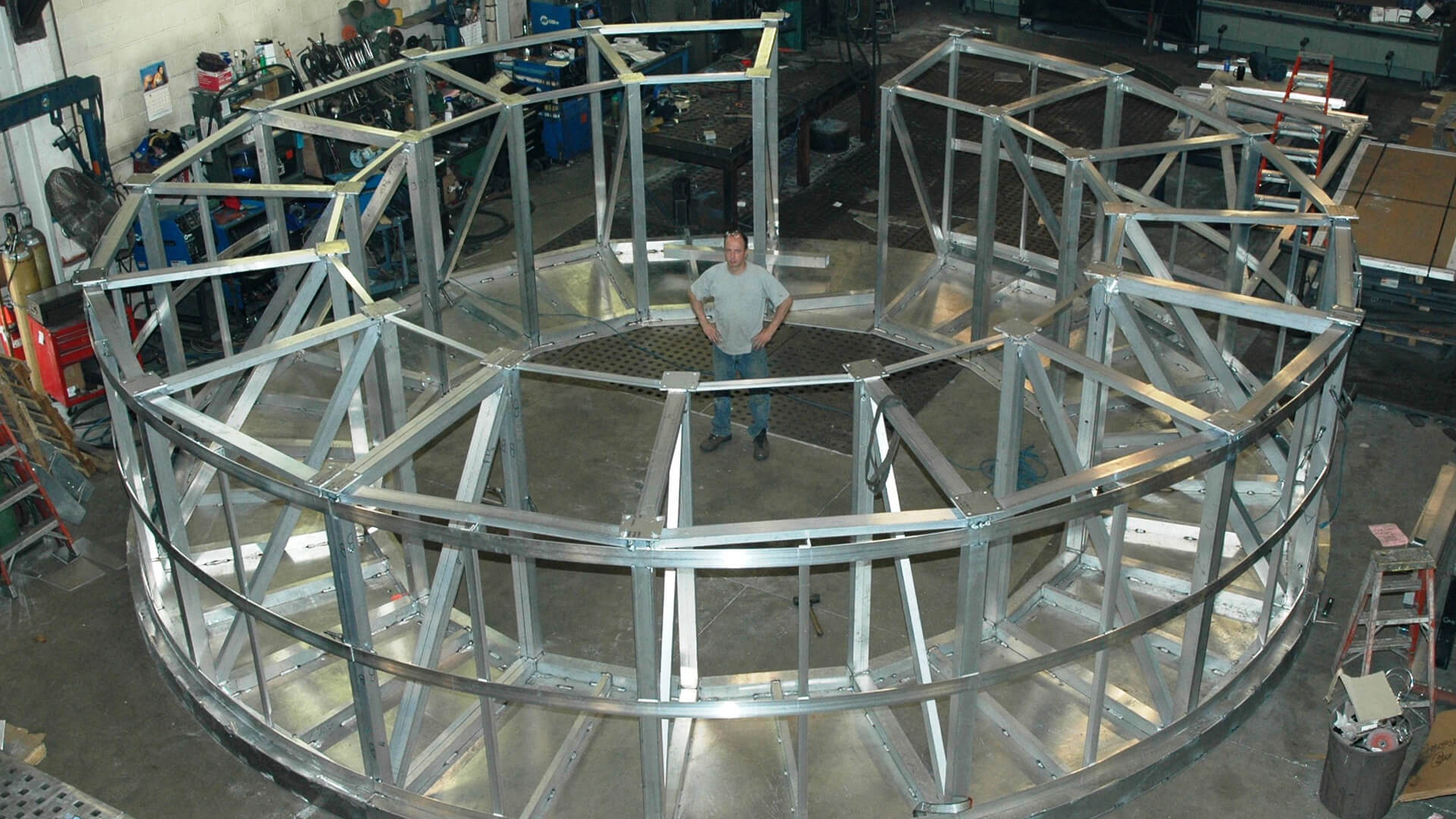

When a project demands metal components at a large scale that other shops can’t handle, Gilchrist Metal Fabricating Company is often called. For five decades, we’ve specialized in large fabrications that push the limits of size, weight, and complexity. With a 70,000 ft facility in Hudson, New Hampshire, and a culture of problem-solving, GMFCO has earned its place among the most respected “large part” fabricators in New England.

What really sets us apart is how we consistently deliver oversized projects from massive large CNC-machined parts to fully welded and formed assemblies—with the precision and reliability today’s industrial manufacturing and construction projects demand.

Uniquely Oversized Projects

Handling large and complex parts requires more than just large equipment. It requires a mindset. The workflow must be designed for size and scale. Large components present unique challenges:

- Material handling – Safely moving parts weighing several tons requires cranes, rigging expertise, and floor space.

- Precision at scale – A one-millimeter tolerance on a 10-foot part is far more challenging to achieve than on a smaller piece.

- Integrated processes – Projects usually require multiple disciplines—cutting, bending, machining, welding, stress relieving, and assembly—all coordinated seamlessly.

GMFCO has developed its operations around these realities, making “large and complex” not the exception, but the standard. As our motto states, where others see challenges, we see opportunity.”

Large CNC Machining: Accuracy at Scale

One of our most requested specialties is large CNC machining. When clients are looking for a large CNC machining shop, they tend to look at experience and capabilities. For example GMFCO offers the ability to handle parts up to 275″ long, 157″ wide, 96″ tall, and weighing as much as 44,000 pounds. With needs approaching these dimensions come up, large part clients quickly discover how few shops can truly deliver.

Our investment in advanced equipment like the AWEA double-column, 5-face machining center ensures that large size doesn’t mean sacrificing accuracy. Our team can execute multi-axis milling, drilling, and finishing in a single setup, saving clients time and ensuring precision.

Whether a project requires a one-off large CNC machining service or repeat production runs of oversized parts, we bring agility and expertise to meet demanding schedules.

Beyond Machining: Fabrication Services Built for Size Needs

Large projects rarely stop at machining. They often require large forming, welding, and finishing as part of a complete solution. GMFCO is structured as an integrated fabricator, meaning our facility houses:

- Large custom CNC milling services for components needing fine detail and accurate surfaces.

- Large metal machining capabilities that complement fabrication, allowing us to machine both welded assemblies and standalone parts.

- Large metal bending services, including press brakes with high tonnage and size capacity.

- A large steel bending shop where heavy structural sections and plate can be formed to spec.

Having all these services under one roof means fewer logistical hand-offs, tighter project control, and a smoother path from raw stock to finished product. It adds up to a competitive advantage for our customers.

Facilities Designed for Large-sized Work

Our facilities have been built and expanded with scale in mind. High bay ceilings, 15-ton overhead cranes, wide open floor space, and state-of-the-art machinery all support the efficient handling of massive parts and assemblies. Some projects even call for parts that simply won’t fit through the doors of a conventional shop—or can’t be handled by typical lifting systems, but GMFCO is prepared for all of this.

The layout of our plant allows work to flow from cutting to machining to welding to finishing without bottlenecks, even when handling multi-ton pieces. This kind of environment isn’t an afterthought, it’s an intentional design that makes oversized fabrication practical and efficient.

A Skilled Team That Thrives on Challenge

Technology and equipment are important, but large-part fabrication requires an experienced and skilled team capable of problem-solving in real time. GMFCO’s welders, machinists, and fabricators are cross-trained and experienced in handling the unexpected challenges that come with the big projects.

From fixturing enormous assemblies like slotted pole antenna masts, to ensuring precise weld quality on thick sections of marine enclosures, our people take pride in delivering work that not only meets but exceeds specifications. Continuous improvement and a culture of safety help ensure that every oversized project is finished with the same level of detail and care, quality assured.

What Really Matters for Our Customers

For clients in industrial manufacturing, construction, marine, utilities, and other sectors, the ability to work with a partner that can handle oversized parts has major business impacts:

- Reduced risk – Projects aren’t delayed by outsourcing different phases to multiple vendors.

- Reliable quality – One team overseeing machining, bending, and welding ensures standards remain high across the board.

- Faster timelines – Integrated processes and in-house capabilities shorten lead times.

- Scalability – GMFCO can support everything from prototypes to production runs.

Tackling the Next Oversized Challenge

We don’t see challenges as obstacles but rather opportunities to demonstrate our real differentiation. Our 70,000 ft facility, advanced equipment, and experienced team make us the partner of choice for organizations that need a partner.

If you’re looking for a proven large CNC machining service or a fabrication partner capable of large metal bending, forming, and assembling large sized parts with precision, we invite you to call us. GMFCO is ready to take on your large cnc machining and fabricating project and deliver world class results.