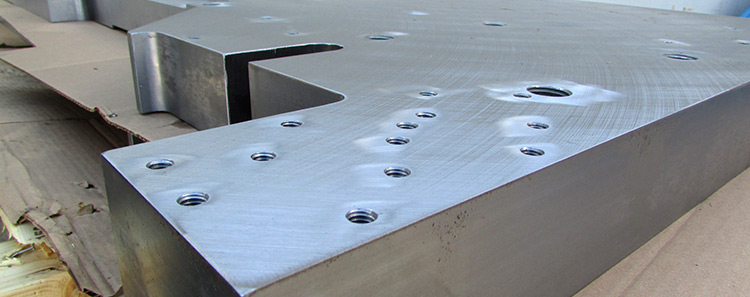

Since our doors first opened, one of GMFCO’s greatest specialties has been large CNC machining. In our modern facility, know-how and extensive capabilities come together to make us one of few CNC machining companies in New England that can deliver the range of large machining services we offer under one roof.

At GMFCO, our drive to consistently offer more is what makes us different. By combining technology and experience, finding a solution where others might only find trouble is our specialty.

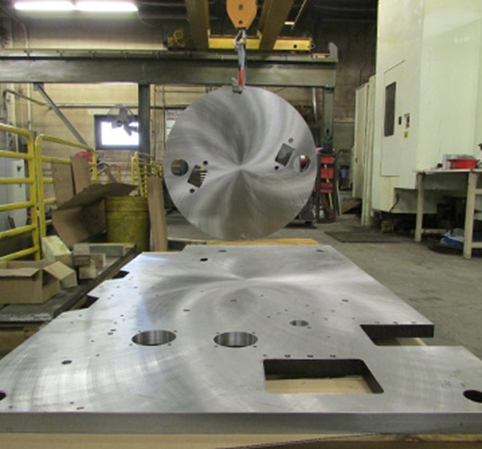

*NEW* AweA Double Column 5-Face Machining Center: for components as large as 275” Long x 135” Wide x 96” high x 44,000lbs

CNC Horizontal Machining: Toshiba CNC Horizontal Boring and Milling: 5th Axis Rotary Table 98“ X, 70“ Y x 57“ Z, 3000 RPM.

CNC Vertical Machining: Mori Seiki NV 5000; 12,000 RPM spindle speed, 2.6 second chip to chip tool change time

Quickmill Gantry Machining Center with Pipe Rotation Fixture: 5 ft x 27 ft, Rotary Position of pipe and tube up to 75 ft long, 6000 RPM

For every large machining project, we work with our customers from the very beginning to ensure the best possible end-result. Being able to handle most large machining projects under our own roof also enables our experienced quality team to maintain constant

With years of experience providing machining for industries ranging from aerospace and defense to the architectural industry, customers with any large machining need regularly turn to our team to deliver the precision, communication, and end-result they depend on.

Maximum Size: 275" Long x 157" Wide x 96" High X 44,000 LBS

Multi Axis Machining: 4 and 5 Axis Machining

*NEW* AweA Double Column 5-Face Machining Center: for components as large as 275” Long x 157” Wide x 96” high x 44,000lbs

CNC Horizontal Machining: Toshiba CNC Horizontal Boring and Milling: 5th Axis Rotary Table 98“ X, 70“ Y x 57“ Z, 3000 RPM.

CNC Vertical Machining: Mori Seiki NV 5000; 12,000 RPM spindle speed, 2.6 second chip to chip tool change time

Quickmill Gantry Machining Center with Pipe Rotation Fixture: 5 ft x 27 ft, Rotary Position of pipe and tube up to 75 ft long, 6000 RPM