Every day, Gilchrist Metal Fabricating Company produces aluminum fabrications for customers in industries everywhere. For every project, time is of the essence.

Fortunately, we have time on our side. At GMF we’ve used our 30 years of experience to become an aluminum welding, machining, and fabrication resource that yields the time and cost savings every project can benefit from.

Whether your applications are on land, at sea, or in the air, GMFCO is the one-stop aluminum fabricator you’re looking for.

The Gilchrist “difference” isn’t just experience, because experience alone never ensures quality. The real difference is what we’ve done with it.

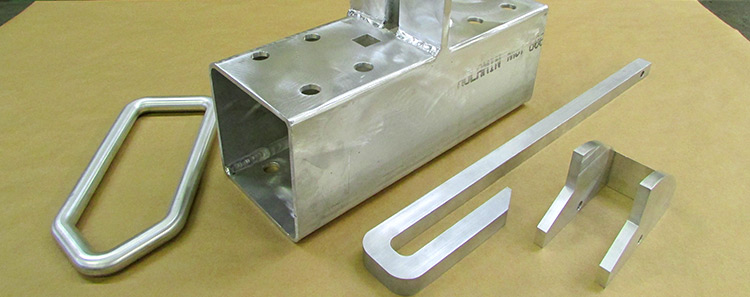

That is, using our extensive experience to assemble industry leading project support, cutting edge technology, and machining expertise. This has allowed us to produce large, small, and complex aluminum fabrications for applications ranging from microwave testing and telecommunications to architectural design and beyond.

GMFCO’s dedicated approach to custom aluminum fabricating makes every customer’s life easier. Why? Because before we turn on any machine, we ensure that every customer is confident that their project is in the best possible hands, from planning to delivery.

GMFCO continues to be the aluminum fabricating company of choice throughout the New England area and beyond. We invite you to browse through our website to learn more about the wide breadth of our capabilities.

Copyright © GMFCO.com 2026